Mobile Food Vendor Inspection Information and Requirements

This information helps mobile food vendors understand the key safety requirements, inspection procedures, and operational guidelines necessary to operate legally and safely within the City of Bryan.

Whether you’re just getting started or preparing for an upcoming inspection, this guide provides clear answers to the most common questions we receive from food truck and trailer operators. Topics include fire extinguisher requirements, propane safety, hood system maintenance, equipment securement, and more.

Our goal is to support your success while ensuring public safety. If your question isn’t covered here, please don’t hesitate to contact the Bryan Fire Marshal’s Office directly through our email form. We’re here to help.

Type I hoods must be serviced by a qualified technician at least every six months and cleaned regularly to prevent grease buildup. Prior to scheduling an inspection, please ensure your hood system has a current service tag and is in full compliance with applicable fire safety requirements.

Do You Need a Type I Hood?

Understanding Grease-Laden Vapors

If you own or operate a mobile food truck or cart, it’s important to understand the term “grease-laden vapors” — because it directly affects your fire safety requirements.

Grease-laden vapors are the smoke, steam, fumes, and particles released into the air when cooking with oils, fats, or grease at high temperatures. These vapors can collect on surfaces and in ventilation systems, creating a serious fire hazard if not properly captured and controlled.

Common cooking methods that produce grease-laden vapors include:

- Frying (deep or pan)

- Grilling (flat tops or charbroilers)

- Sautéing

- Broiling

- Cooking with woks or tilt skillets

If your food truck uses equipment for any of the above methods, you likely need a Type I hood with an automatic fire suppression system.

How to Know If You Need a Type I Hood

- Check the equipment – Does it use oils, fats, or high heat? Does it produce visible smoke or vapors?

- Look for manufacturer requirements – Some appliances are labeled with hood requirements.

- Consult local fire codes or inspectors – They can evaluate your setup and confirm whether a Type I hood is required.

Installing the right ventilation and suppression system isn’t just about code compliance — it’s about protecting your staff, your customers, and your business.

Need help? Our office can help review your setup and guide you through the inspection process. Schedule a mobile vendor safety inspection or contact us with questions.

Required Inspections for a Type I Hood in Mobile Food Units

Type I hoods are subject to specific inspection and maintenance requirements to ensure they remain effective and safe.

Semi-Annual Fire Suppression System Inspection

The fire suppression system connected to the Type I hood must be professionally inspected and serviced every 6 months by a licensed fire protection contractor. This inspection includes:

- Verifying the proper operation of nozzles, detection devices, and cylinders

- Confirming coverage of all protected cooking appliances

- Ensuring the system is charged, armed, and tagged

- Updating the inspection tag with the service date and technician license number

Units without a current suppression system tag will not be approved and may be prohibited from operating.

Cleaning Requirements for Mobile Food Vendor Hoods

Proper hood cleaning is essential to preventing grease fires and ensuring the overall safety of your mobile food unit. Cooking with oils and fats generates grease-laden vapors that accumulate on the surfaces of your ventilation hood and ductwork. If not regularly cleaned, this buildup becomes a highly flammable fire hazard.

Why Hood Cleaning Matters

- Grease accumulation can ignite and spread rapidly, especially in confined spaces like food trucks and trailers.

- A dirty hood reduces ventilation efficiency, leading to heat buildup, poor air quality, and increased risk of fire.

- Failure to maintain a clean hood may result in inspection failure, citation, or shutdown of operations.

What the Bryan Fire Marshal’s Office Requires

Unlike traditional commercial kitchens, mobile food vendor hoods are generally more accessible for routine cleaning. For this reason, the Bryan Fire Marshal’s Office does not require mobile vendors to use a certified hood cleaning company. However:

The hood system shall be cleaned and maintained in such a way that the hazards of grease accumulation are not present.

This means:

- All surfaces of the hood, including filters and interior panels, must be kept free of heavy grease buildup.

- Cleaning must be performed frequently enough to prevent visible accumulation and odor.

- Filters must be removable and cleaned or replaced regularly as part of your maintenance routine.

Non-Compliance Consequences

- Hoods that show excessive grease or are determined to be a fire hazard will not be approved during inspection.

- Mobile food vendors may be issued a citation for failing to maintain the hood system in a clean and safe condition.

Best Practices

- Clean hood filters daily or weekly, depending on use.

- Wipe down all interior hood surfaces at the end of each workday.

- Use degreasers and non-abrasive tools appropriate for stainless steel.

- Inspect and document your cleaning schedule to demonstrate maintenance efforts if questioned during an inspection.

A clean hood is not just a code requirement—it’s a critical part of protecting your business, your employees, and your customers from fire risk. If you need help understanding what’s required or how to clean your specific system, the Bryan Fire Marshal’s Office is here to help.

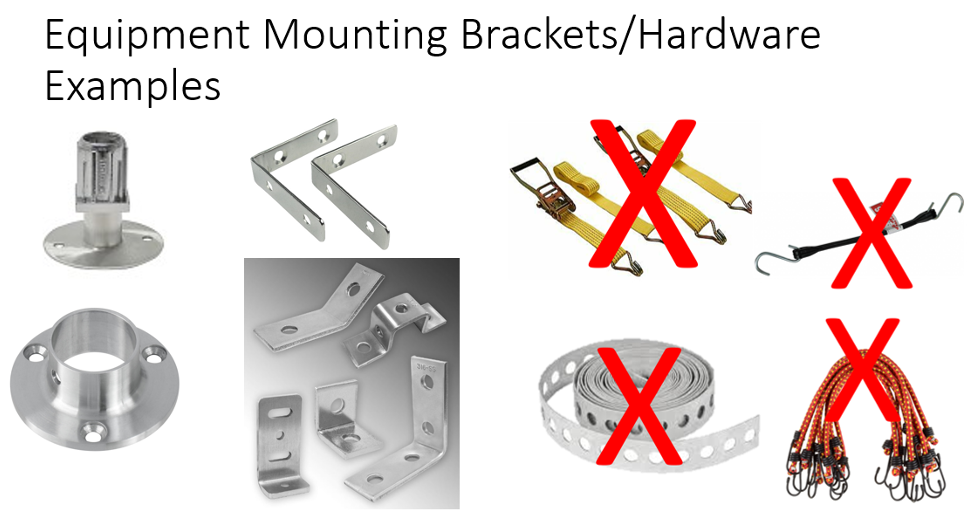

Securing Mobile Food Vendor Equipment

Appliance Mounting Requirements for Mobile Food Vendors

For the safety of your staff, customers, and equipment, all cooking and electrical appliances must be permanently mounted to the interior structure of your food truck or trailer. This means appliances must be securely bolted, anchored, or otherwise fastened using hardware or brackets designed to withstand movement and vibration during both operation and transport.

What Is Not Allowed

Temporary restraints such as:

- Ratchet straps

- Rubber tie-downs

- Bungee cords

These are not considered permanent securement methods and are not permitted for holding appliances in place during cooking or transit. These types of restraints can stretch, fail under stress, or allow appliances to shift, creating a significant fire, electrical, or injury hazard.

Exceptions (Transit Use Only)

Temporary straps may be used solely to secure non-hazardous components during transportation, such as:

- Refrigerator or freezer doors

- Cabinet doors or drawers

- Loose, lightweight equipment stored off the cooking line

Fire Extinguisher Requirements

Minimum Requirement for All Units

If your mobile food unit does NOT have a Type I cooking hood or a portable/fixed generator, you are required to have at least one (1) 2A:10B:C fire extinguisher (or larger).

This multipurpose extinguisher covers:

- Class A fires – Combustibles like wood, paper, and cloth

- Class B fires – Flammable liquids such as cooking oils and fuels

- Class C fires – Electrical equipment

Additional Requirements Based on Equipment

1. Class K Fire Extinguisher (Required if You Have a Type I Hood)

If your unit is equipped with a Type I cooking hood, you must have a Class K fire extinguisher, which is specifically designed for grease-related cooking fires.

- This is required in addition to the 2A:10B:C extinguisher.

- Mounting Recommendation: Due to its heavier weight and the lightweight interior construction of most food trucks and trailers, mount the Class K extinguisher on the floor in a secure upright position rather than on a wall bracket, which can fail during transit.

2. Class 2A:20B:C Fire Extinguisher (Required if You Have a Generator)

If your mobile food unit uses a portable or fixed generator, you are required to have a Class 2A:20B:C fire extinguisher to address the increased risk of fuel and electrical fires.

- This extinguisher is in addition to the 2A:10B:C unit if your setup includes both a hood and a generator.

- Mount in a location that is easily accessible but protected from weather and mechanical damage.

Mounting & Accessibility Guidelines

- All extinguishers must be mounted in a secure, upright position and be readily accessible during normal operations.

- Do not store extinguishers inside cabinets, behind doors, or blocked by supplies.

- Staff must be trained in the location and proper use of each extinguisher.

Ensuring your extinguishers are properly rated, mounted, and accessible is a critical step toward keeping your mobile food operation safe and compliant. Need help with layout or inspection? Contact our office for guidance.

Mounting & Accessibility Guidelines

When purchasing a fire extinguisher, it’s crucial to verify its classification rating to ensure it meets the specific fire safety requirements of your operation. The UL rating, such as 2A:10B:C, indicates the extinguisher’s effectiveness against different classes of fires.

To locate this rating on the packaging, examine the front or side panels. Manufacturers typically display the UL rating prominently on the front or side of the box. Look for a label or printed text stating the classification, e.g., “2A:10B:C”.

Fire Extinguisher Inspection and Tagging Requirements for Mobile Food Vendors

To ensure your fire extinguishers will work when needed — and to stay compliant with fire code requirements — annual inspection and verification of service are mandatory. This applies to all fire extinguishers on your mobile food unit, regardless of type or size.

You have two acceptable options to meet the annual inspection requirement:

Option 1: Have the Extinguisher Professionally Inspected and Tagged

- A licensed fire protection contractor can inspect your extinguisher and apply a dated inspection tag showing it has passed the required checks.

- This tag is valid for one year from the date of inspection.

- Make sure the tag is clearly visible and securely attached to the extinguisher.

This is the preferred option for most mobile vendors and is required if your extinguisher is refillable (like most Class K extinguishers).

Option 2: Purchase a New Extinguisher Each Year

- You may choose to replace your extinguisher annually with a new one from a hardware store or commercial supplier.

- The purchase receipt serves as proof of compliance for the first year of service.

Important: Most receipts are printed on thermal paper, which can fade quickly when exposed to heat or sunlight—common conditions in mobile food trucks.

Make a photocopy of the receipt or take a photo and keep it stored in a safe, accessible place. If you can’t prove the purchase date, the extinguisher may be considered out of compliance during inspection.

Propane Tank Restraint Requirements for Mobile Food Vendors

Propane is a highly flammable fuel commonly used in mobile food units, and its safe handling is essential. One of the most important safety measures is ensuring that all propane cylinders are properly restrained to prevent shifting, tipping, or impact during transit and operation.

Why Proper Restraint Matters

Unsecured propane tanks can move while driving or during setup, which may result in:

- Damage to hoses, regulators, or valves

- Leaks or ruptures, increasing the risk of fire or explosion

- Equipment malfunction or service interruptions

Acceptable Methods of Restraint

Propane tanks must be secured using rigid, non-flexible hardware that can withstand the stresses of transit and vibration. Acceptable methods include:

- Metal brackets or cages

- Rigid chains bolted to structural framing

- Straps rated for load-bearing use (e.g., ratcheting metal tie-downs, not rubber or bungee-style)

Unacceptable Restraint Methods

- Mounted upright and in a ventilated location

- Positioned so that valves and hoses are protected from impact or crushing

- Easily accessible for shutoff in the event of an emergency

Properly Restrained Tanks Should Be:

- Mounted upright and in a ventilated location

- Positioned so that valves and hoses are protected from impact or crushing

- Easily accessible for shutoff in the event of an emergency

Unacceptable Restraint Methods

- Rubber straps

- Bungee cords

- Lightweight or elastic materials

These items are not permitted as they can stretch, deteriorate in heat, and fail to keep the tank secure under real-world conditions. They are considered temporary and unreliable, and their use may result in code violations or failed safety inspections.

Propane Gas Alarm Requirements for Mobile Food Vendors

Propane is a popular and efficient fuel source for mobile food operations—but it also presents a serious safety hazard if not properly monitored. Because propane is heavier than air, it tends to collect in low areas like under counters or inside cabinets, where leaks can go undetected until it’s too late.

To protect against this risk, propane gas alarms are required in all mobile food units that store or use propane. These alarms are a critical early warning system that can alert you to a leak before it leads to a fire or explosion.

The Most Dangerous Time

The highest risk of propane buildup is when the truck or trailer is not in use—overnight, in storage, or between events.

That’s why it’s essential that propane alarms remain powered at all times, even when the unit is parked or closed. If the alarm is not powered during these idle periods, you lose your only line of defense against a silent, accumulating gas leak that could ignite the moment a switch is flipped or a door opens.

Options for Compliant Propane Alarms

There are several types of propane alarms available to meet this requirement:

- Hardwired Alarms

- Connected directly to the unit’s 12V or 120V electrical system.

- Offers continuous monitoring as long as vehicle power is available.

- Ideal for food trucks with permanent wiring.

- Plug-In Alarms

- Plug into a standard outlet and operate on 120V power.

- Suitable for trailers that are frequently connected to shore power.

- Ensure your inverter or battery system provides continuous power when disconnected.

- Battery-Backup Alarms

- Some propane alarms include a battery backup in case of power loss.

- Useful in mobile setups where power interruptions are common.

- Check and replace batteries regularly.

Installation Tips

- Install the alarm low to the ground, where propane would settle.

- Do not block or cover the alarm with equipment or supplies.

- Test the alarm regularly, and replace it according to the manufacturer’s instructions (usually every 5–7 years).

- Consider installing multiple alarms in large or multi-compartment setups.

In short, a propane alarm is a small investment that provides life-saving protection. Make sure it’s installed, powered, and maintained properly—especially during downtime—so that your mobile food operation stays safe and compliant at all times.

Need help choosing or installing a propane alarm? Contact our office for approved models and guidance.

Power Inverters and Electrical Safety for Mobile Food Vendors

Power inverters are commonly used in mobile food units to convert battery-stored DC power (typically 12V or 24V) into usable AC power (usually 120V) for appliances and equipment. While inverters offer a flexible and quiet power solution, they can also pose significant fire and electrical hazards if not installed correctly—particularly when it comes to wiring and circuit protection.

Why Proper Wiring and Protection Matter

High-output inverters draw a large amount of current, especially under load. Using undersized wires or improperly rated breakers can lead to:

- Overheated wiring

- Melted insulation

- Electrical fires

- Equipment damage or failure

This is especially dangerous in mobile food trucks and trailers, where confined spaces and combustible materials increase the risk of fire spreading rapidly.

Common Sizing Requirements

While exact specifications depend on the inverter’s wattage and voltage, typical mobile food vendor setups may include:

| Inverter Size (Watts) | Typical Breaker Size | Minimum Cable Gauge (Copper, <10 ft run) |

|---|---|---|

| 1000W | 100A | 2 AWG |

| 2000W | 200A | 1/0 AWG |

| 3000W+ | 250–300A | 2/0 to 4/0 AWG |

Note: Always refer to the inverter manufacturer’s installation guide for specific wire gauge, breaker size, and fuse type recommendations based on your cable length and system voltage. The examples above are for illustrative purposes only.

Breaker Mounting & Protection

- High-amp DC breakers or fuses must be installed as close as possible to the battery—ideally within 18 inches of the battery terminal. This prevents the wiring from overheating in case of a short.

- Use marine-grade or inverter-rated breakers/fuse blocks designed for high-amperage DC loads.

- Make sure breakers or fuses are easily accessible for inspection or replacement.

- Never mount fuses inside engine compartments or near combustible materials without proper enclosures./li>

- Secure wires with clamps to prevent vibration damage or abrasion.

- Always use properly rated insulation and cables approved for automotive or marine environments.

Note: We recommend having the system reviewed or installed by a licensed electrician or certified RV technician.

An inverter is a powerful tool for mobile food vendors—but without the right wire gauge and breaker protection, it becomes a serious safety risk. Ensuring your system is built to code and manufacturer specifications is essential to preventing fires, equipment damage, or inspection failure.

If you’re unsure whether your inverter setup is safe or compliant, the Bryan Fire Marshal’s Office is available to review your configuration or refer you to qualified professionals.